milling machine parts and functions pdf

The problem is the quality issues abound with the parts on this machine. Cutting fluid washes away the chips and hence keeps the cutting region free.

Tension and torsion experienced by the tool as well as the bending moments in the x and y directions denoted by m x and m y respectively.

. Download Free PDF Download PDF Download Free PDF View PDF. Machine shop notespdf 1. An average vise for the machine would be 60 mm high.

Genmitsu CNC 3018-PRO Router Kit GRBL Control 3 Axis Plastic Acrylic PCB PVC Wood Carving Milling Engraving Machine. They improve machinability and reduce machining forces. Numerical control also computer numerical control and commonly called CNC is the automated control of machining tools such as drills lathes mills grinders routers and 3D printers by means of a computerA CNC machine processes a piece of material metal plastic wood ceramic or composite to meet specifications by following coded programmed.

Summit Machine Tool 518 N Indiana Ave Oklahoma City OK 73106. 142 Functions or uses of Coolants or Cutting fluids 1. On the workaday shop floor the TNC 620 shines with its intuitive operation high dynamic performance excellent motion control and extensive functionality delivering a perfect outcome on your universal milling or drilling machine with both speed and efficiency.

Large 5-Axis CNC Milling Machines. Fast access to spare and replacement parts can help you control costs protect capital investments extend the life of equipment and maintain production levels. A punch press machine is used in the deformation of metal by applying pressure to the die attached to the workpiece.

08 Flame-heated surface quenching. So to overcome this problem the machine manufactured is CNC which is known as Computer Numerically controlled. Produces and sells machine tools complemented by a wide range of services and accessories.

420 412 351 234. User Guides tutorial and training. Solutions Manual of Degarmo 9th edition.

Flexible milling and drilling. The data is sampled at 1600 Hz and a typical data set has m 1500020000 samples depending on the length of the lane being cutThe first 20 of a. The tutorial will guide you through the set-up procedure using the ATC tools.

This types of machine Vice has been shown in Figure. Its advantage is that without separating the job from the vice straight or angular machining can be done. The cutting tool and the feed rate of the work piece depend upon the type of material being machined.

By Innovative Research Publications. Design and Analysis of Indexing Type of Drill Jig. TPI SHOP ERP for manufacturing and service.

In construction and shape this vice is similar to a flange machine vice but its base is different with the help of this base the vice can be revolved at any angle. Since the thickest blocks of aluminium easily available for me would be 60 mm high as well I chose to space between the work surface and the piece of metal which could hit the workpiece first to be 125 mm. Use the optional ATC rack up to 8 tools for milling drilling and rigid tapping applications The CNC Masters Automatic Tool Changer Rack and Tools US Patent 9827640B2 can be added to any CNC Masters Milling Machine built with the rigid tapping encoder option.

The thread mills can be used on CNC machining centers that have simultaneous triaxle control and helical interpolation functions. Thread milling using either solid carbide thread mills or steel holders with indexable inserts. Effect of Change in Material and Production Process on Cycle Time Production Rate Cost and Impact Strength of Plastic Product.

Download Free PDF Download PDF Download Free PDF View PDF. HROEPC 62017 8 Qualities of Overseas Employees Overseas employees will demonstrate the following characteristics essential for being a successful member of the United States Embassy Consulate or Mission team. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our.

The real-time data acquired from the machine has four relevant channels. We feature a dedicated parts team and a million dollar inventory of ready-to-ship machine tool supplies lathe parts and machine tool accessories for Summit equipment. 1 Steel parts should be cold treated immediately after quenching and then tempered at low temperature to eliminate internal stress during low temperature cooling.

Access this document from VCarve Pro s Help Menu Help Contents or from the VCarve Pro folder in the program section of your Windows Start menu. Download Free PDF Download PDF Download Free PDF View PDF. A machine shop or engineering workshop UK is a room building or company where machining a form of subtractive manufacturing is doneIn a machine shop machinists use machine tools and cutting tools to make parts usually of metal or plastic but sometimes of other materials such as glass or woodA machine shop can be a small business such as a job shop or a.

Lets understand in detail and also at the end of the article I. Using the manual control functions of the grbl software handling system we are now able to control the Y Z and X axis. PDF Presented paper concentrate on problems connected with the function of operation management within the company.

TARUS Service Parts Support. 2 Cold treatment is mainly applicable to tight tools measuring tools and tight parts made of alloy steel. Varying thread milling tool or cutters enables the production of threads from internal to external medium to large sizes.

Design and fabrication of work holding device for a drilling machine. Coordinate Measuring Machines Services. As we know machines like lathe Milling Drilling the operation are performed manually and there is more involvement of humans to perform and time taking is high average precision and accuracy.

Most of the work I planned to do with the CNC involved milling aluminium parts. Claymilling Car Design Studio Solutions. This manual is designed to provide a comprehensive description of all the functions tools menus and icons available within the VCarve Pro software package.

The main functions of the punch press are punching notching piercing slotting and perforating. We have prepared for you a summary of unique technical solutions and special functions that make our machines exceptional. Composure and IntegrityTo stay calm poised and effective in stressful or difficult.

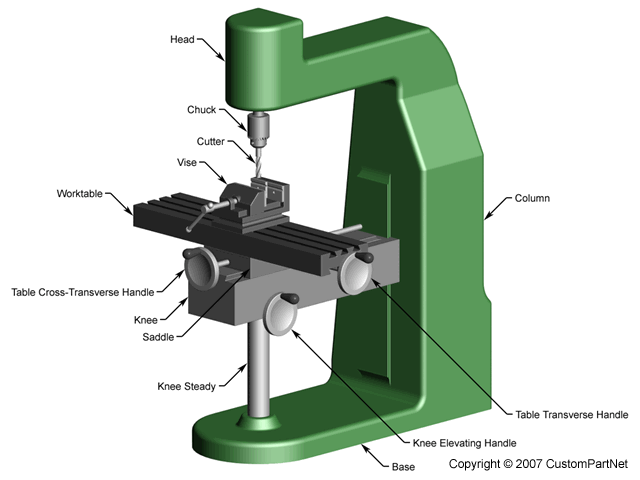

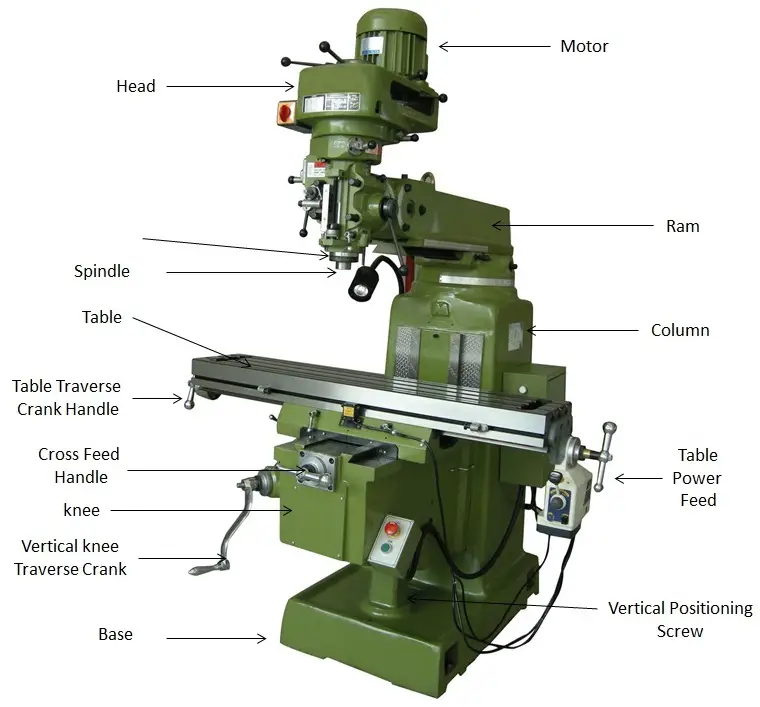

Milling Machine An Overview Sciencedirect Topics

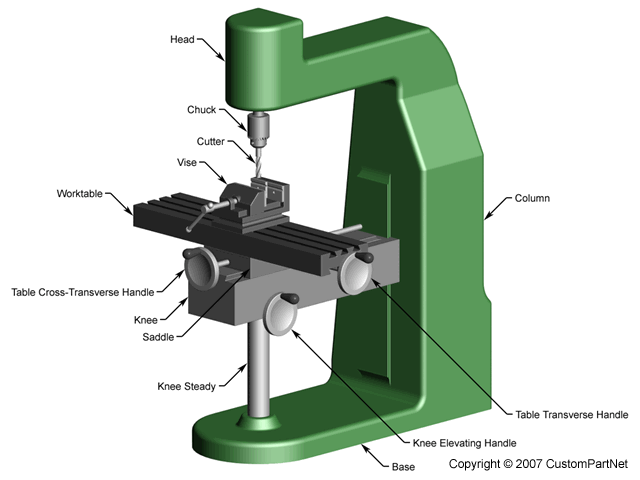

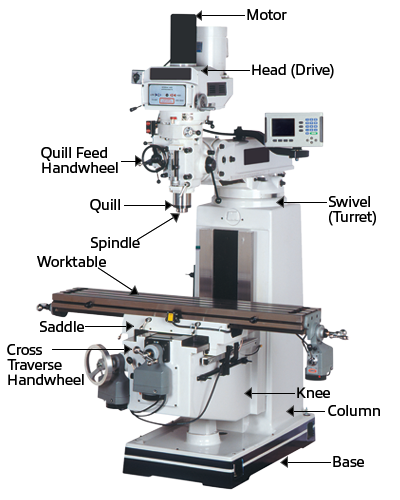

What Is Milling Machine Operation Parts And Types Mechanical Booster

Cnc Milling Machine Parts Complete Diy Guide Cnccookbook Be A Better Cnc Er

Cnc Machining Vs Manual Machining Which Is Better Rapiddirect Blog

Cnc Milling Machine Parts Complete Diy Guide Cnccookbook Be A Better Cnc Er

Milling Machine Definition Parts Types Operations With Pdf Learn Mechanical

How To Use A Milling Machine Instructions

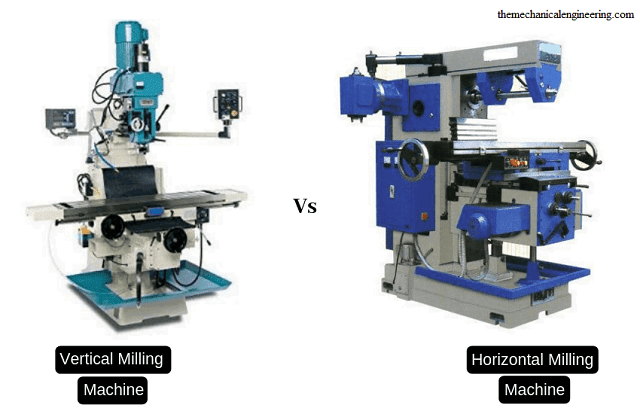

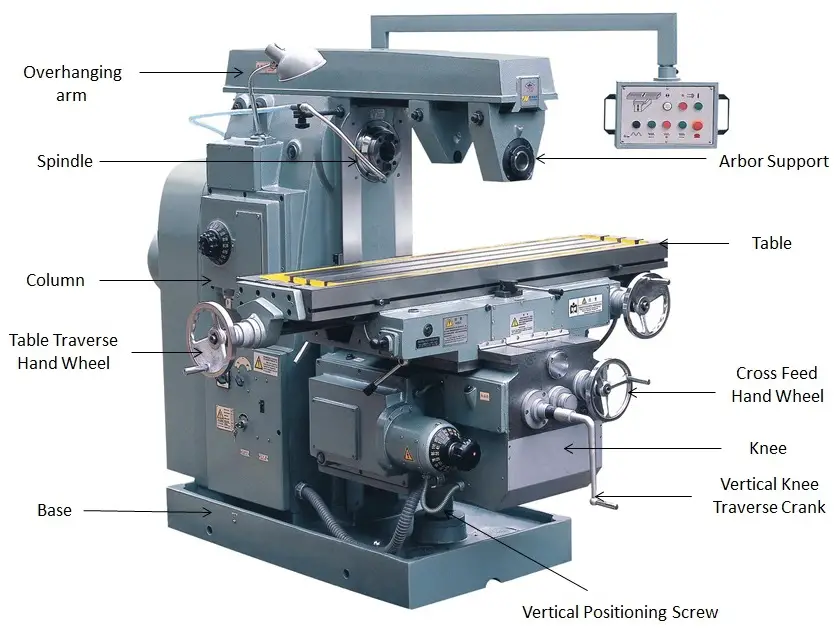

Difference Between Horizontal And Vertical Milling Machine Notes Pdf

Grinders Lathes Mills Edms Radial Arm Drills Kent Industrial Usa

Modela Pro Ii Mdx 540 3d Milling Machine Roland Dga

How To Use A Milling Machine Safely Free Step By Step Guide

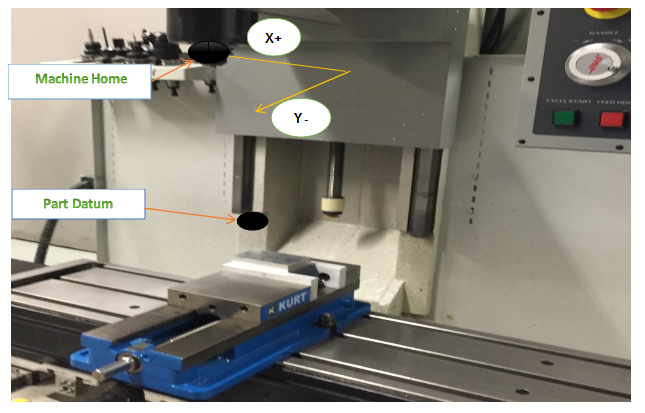

Unit 3 Vertical Milling Center Machine Motion Manufacturing Processes 4 5

Milling Machine Definition Parts Types Operations With Pdf Learn Mechanical

Milling Process Defects Equipment

Horizontal Milling Machine Cad Cam Engineering Worldwide

What Is Milling Machine Operation Parts And Types Mechanical Booster

Msc Industrial Supply Co Tech Essential Mill Machines

Horizontal Milling Machine Cad Cam Engineering Worldwide

What Is Milling Parts Operations And Types Of Milling Machine Youtube